Candle wicks are an essential component in the candle-making process, serving as the conduit for delivering heat to the wax, which ultimately fuels the light of the candle. The wick’s primary function is to transfer the heat generated by the flame into the surrounding wax, allowing it to melt and release fragrance while producing a steady glow. Without an effective wick, even the highest quality wax or fragrance would fail to create an optimal burning experience.

The evolution of candle wicks is as rich as the history of candle-making itself. Initially, ancient cultures utilized rudimentary materials, such as reeds and twisted fibers, to create wicks that were functional, albeit inefficient. As candle-making techniques advanced, so too did the materials used to craft wicks. In contemporary candle production, wicks are often made from cotton, wood, or even paper, each material offering various advantages in terms of burn time, flame height, and scent throw.

Candle wicks not only serve a practical purpose; they also hold cultural significance across different societies. For instance, in religious ceremonies, candles symbolizing light and purity often use specific types of wicks to create a desired ambiance or emotional effect. Whether used for ambiance, rituals, or celebrations, the choice of wick can greatly influence the candle’s overall effectiveness and appeal.

Additionally, the characteristics of the wick—such as its thickness, fiber composition, and treatment—can significantly impact the burning characteristics of a candle. A well-designed wick ensures a clean burn with minimal soot production, enhancing both safety and aesthetic appeal. As we delve deeper into the world of candle wicks, it becomes evident that they are a vital aspect of candle-making that warrants careful consideration and selection.

Types of Candle Wicks

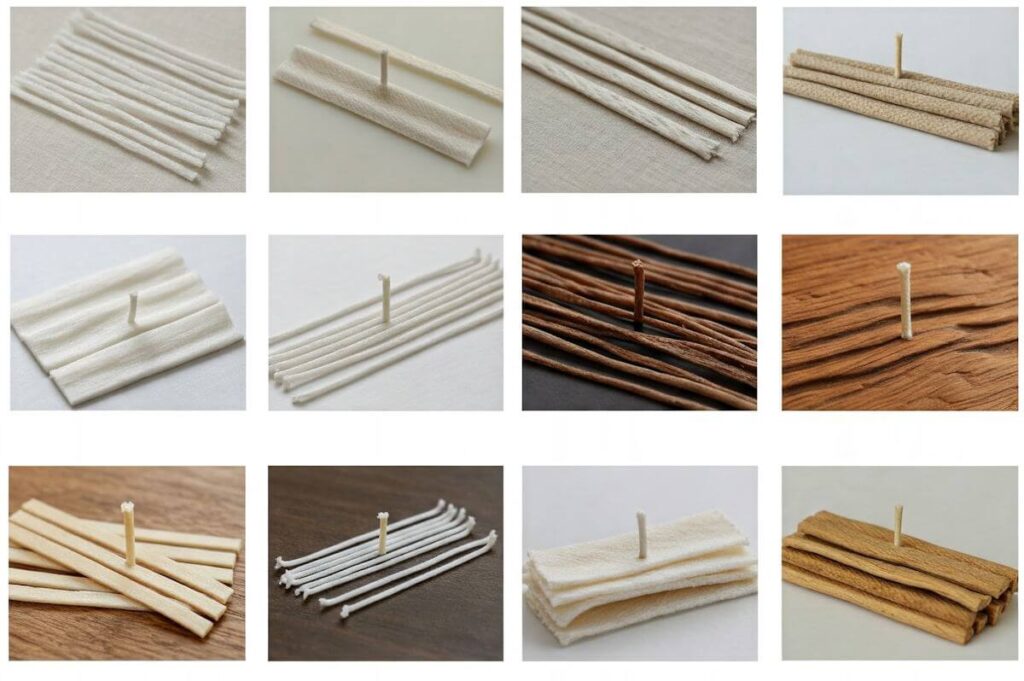

Candle wicks play a crucial role in the performance and efficacy of a candle, and understanding the different types available can aid in selecting the appropriate wick for specific needs. The primary materials used in candle wicks include cotton, wood, and metal, each offering unique characteristics that influence the candle’s burn quality and fragrance throw.

Cotton wicks are the most common and are often made from braided or twisted fibers. These wicks are prized for their clean-burning properties and versatility, making them suitable for various wax types, including paraffin, soy, and beeswax. The braided cotton wicks tend to have a larger surface area, which can facilitate a more substantial flame and produce a more robust scent throw. In contrast, twisted cotton wicks are better for smaller candles, as they maintain a more controlled burn.

Wooden wicks have recently gained popularity for their aesthetic appeal and unique crackling sound when burned, reminiscent of a fireplace. They are typically made from thin slices of hardwood and are best suited for larger candles. Wooden wicks require specific wax combinations to ensure a proper burn, which can lead to an enhanced sensory experience through sight and sound.

Metal wicks, although less common, offer durability and can provide steady flames due to their structural stability. These wicks are often found in specialty candles and are typically used in combination with other materials to optimize performance. Choosing the right wick material is essential for achieving desired effects, whether for ambiance or fragrance diffusion.

The differences between braided and twisted cotton wicks highlight how even slight variations can impact the overall candle experience. Understanding these nuances can assist consumers in making informed choices that align with their preferences and needs for candle use.

Material Matters: Cotton Wicks

Cotton wicks have become a popular choice among candlemakers due to their affordability and superior burning properties. These wicks are typically made from 100% natural cotton fibers, which allow for an efficient and consistent burn. Cotton wicks are lead-free, making them a safer option compared to some older wick types. This characteristic is particularly important to consumers who prioritize health and safety in their home environments.

Various types of cotton wicks exist, each designed to cater to specific candle-making needs. For instance, in addition to standard untreated cotton wicks, there are treated options that are coated with substances to enhance their performance. These treatments can help control the wick’s burn rate, impacting both the longevity and flame size. When choosing a wick, it is crucial to consider the treatment, as it can affect how the wick responds to different wax types, fragrance oils, and additives. Proper selection ensures an optimal scent throw and impressive burn quality.

Another vital aspect of cotton wicks is their sizing. They come in various diameters and lengths, making it essential to match the wick size with the dimensions of the candle. A wick that is too small may struggle to create enough heat to melt the wax efficiently, leading to a tunnel burn and ineffective scent diffusion. Conversely, a wick that is too large may produce a flame that is too intense, resulting in soot and excessive wax consumption. Thus, understanding the specifications of cotton wicks plays a crucial role in achieving an ideal candle experience.

Ultimately, cotton wicks are widely regarded for their versatility and performance in candle making. Their natural composition and variety of treatments can significantly influence the overall quality of the candle, affecting both the burning characteristics and the aesthetic experience. Therefore, making informed choices regarding cotton wick types will lead to enhanced candle performance and user satisfaction.

Exploring Wood Wicks

Candle wicks play a crucial role in the overall experience of burning candles, and wood wicks, in particular, have gained popularity due to their distinct characteristics. Unlike traditional cotton or hemp wicks, wooden wicks are crafted from thin slices of wood, offering a unique aesthetic appeal. Many candle enthusiasts appreciate the cozy ambiance created by the gentle crackling sound that wood wicks produce when ignited, reminiscent of a fireplace. This auditory component adds a subtle sensory layer that enhances the candle-burning experience.

When discussing wood wicks, it is essential to consider the types of wood commonly utilized. Cedar and birch are among the most popular choices for crafting wood wicks. Cedar, known for its warm and aromatic properties, not only complements various fragrance profiles but also influences the burning characteristics of the candle. Birch, on the other hand, provides a clean, steady burn and is often favored for its ability to create a consistent flame. The type of wood used can significantly impact both the candle’s fragrance throw and its overall burn time, leading to a distinctive experience for the user.

Moreover, wood wicks require specific considerations during the candle-making process. They generally need to be wider and sturdier to ensure a proper burn, and makers often recommend using a wax blend that has a higher melting point to optimize performance. Additionally, the wick must be trimmed correctly to provide an adequate flame, ensure even burning, and prevent excessive soot. The combination of these factors results in a candle that not only looks appealing but also performs efficiently. Wood wicks thus present a unique opportunity for both candle makers and enthusiasts to explore the nuances of burning candles in a sophisticated and enjoyable manner.

The Role of Wick Size and Thickness

The size and thickness of a candle wick are critical factors that directly influence the candle’s overall performance, including its burn rate, flame height, and scent throw. Selecting the appropriate wick for a specific candle formulation and diameter is essential for achieving optimal results. A properly sized wick is crucial for ensuring that the candle burns evenly and efficiently, providing the desired burn characteristics without excessive smoke or soot production.

A thicker wick generally delivers a larger flame, which can enhance the scent throw of the candle and improve burn quality. However, if the wick is too large for the diameter of the candle, it may lead to an uncontrollable flame, resulting in a candle that burns too quickly or produces excessive soot. Conversely, a wick that is too thin can extinguish too easily, fail to melt all the wax around it, or provide inadequate scent throw, ultimately hindering the candle’s performance. Therefore, it’s vital to find an appropriate balance between wick thickness and candle diameter.

When determining the best wick size, consider the diameter of the container or mold, the type of wax used, and any additional additives such as fragrance oils or colorants. Different wax formulations have varying melting points and burn characteristics, which can influence the choice of wick. Generally, candle makers use guidelines based on wax type and diameter, but experimentation may be necessary to achieve the desired outcome. Furthermore, conducting a burn test can help assess the wick’s performance in real conditions, allowing adjustments to be made as needed.

Choosing the right wick is an essential aspect of candle-making. Ensuring the appropriate size and thickness will enhance the overall quality, creating a beautiful and effective candle that burns evenly and efficiently, highlighting the craftsmanship involved in this traditional art.

Impact of Wick Treatments and Coatings

The performance of candle wicks is significantly influenced by various treatments and coatings that are applied during production. These modifications serve to enhance the burning behavior of the wick, making them a crucial aspect of candle making. One common treatment is the use of tabbed ends, which provide stability and ease of placement within the wax. By ensuring the wick remains upright during the cooling process, these tabs contribute to a more consistent and reliable burn, preventing the wick from tilting or sinking into the wax as it solidifies.

In addition to tabbed ends, various coatings are employed to improve the overall functionality of candle wicks. Wax coatings, for instance, help to reduce fraying and improve the wick’s ability to draw wax. This ensures a stable flame and efficient fuel delivery, which directly influences the candle’s burn time and effectiveness. Furthermore, some manufacturers opt for chemical treatments that aim to modify the wick’s combustion properties. These treatments can enhance the wick’s ability to maintain a steady flame and reduce soot production, promoting an overall cleaner burn.

Environmental considerations have led to increased scrutiny of wick treatments and coatings. While treated wicks provide benefits in terms of performance, the materials used in these treatments may raise sustainability concerns. Untreated cotton wicks are often hailed as a more eco-friendly option, as they rely solely on natural fibers without any chemical modifications. In contrast, treated wicks can contain materials that may not be biodegradable or recyclable, adding to the environmental impact of candle production. As consumers become more conscious of their ecological footprint, candle makers are challenged to balance performance with sustainability. The choice of wick treatment ultimately reflects a complex interplay between functionality, user preference, and environmental responsibility.

Candle Wicks and Fragrance Release

The type of wick used in a candle significantly influences not only its burn characteristics but also its ability to effectively release fragrance into the surrounding environment. Different materials, thicknesses, and constructions of wicks contribute to the overall performance of a candle, particularly in terms of how scent is dispersed. Cotton, wood, and multi-wick designs each present unique benefits and drawbacks that can directly impact the fragrance experience.

Wicks composed of cotton are among the most common choices in candle making. These wicks burn cleanly and steadily, allowing for an even melt pool that enhances fragrance throw. The wick’s thickness and the number of strands used can also alter burn rate, which in turn affects how well the scent is released. A thicker wick may produce a more robust flame, which aids in quicker scent diffusion, while a slimmer wick may result in a slower burn and a more measured fragrance release, suitable for delicate scents.

Wooden wicks offer a distinctive burning style and produce a crackling sound, reminiscent of a fireplace, but their effectiveness in scent throw can vary. When paired with fragrances that require higher heat for optimal release, a wooden wick may deliver a satisfying aromatic experience, although it is crucial to ensure proper sizing to avoid excessively fast burn rates that could hinder fragrance distribution.

Another consideration is the relationship between wick type and fragrance load. Higher fragrance loads necessitate careful selection of wick size and material; otherwise, the candle may burn too quickly or unevenly, limiting scent throw. To attain the desired aromatic ambiance, one should experiment with various wick configurations and formulations to find the ideal balance. With the right wick, a candle can fulfill its purpose not just by lighting a space, but by enveloping it in delightful aromas.

Common Problems and Solutions with Candle Wicks

Candle wicks are essential components that significantly influence the burning quality and overall performance of a candle. However, users may experience certain common problems related to candle wicks, such as tunneling, sooting, and wick clogging. Understanding these issues and implementing effective solutions can enhance the user experience and ensure optimal performance from the candle.

Tunneling is a prevalent issue where the wick burns down the center of the candle while leaving a significant amount of wax around the edges. This not only wastes wax but can also affect the candle’s fragrance throw. To prevent tunneling, it is advisable to allow the candle to burn long enough for the top layer of wax to melt completely across the surface, ideally for one hour per inch of candle diameter. Additionally, choosing thicker wicks can help create a larger melt pool, thus mitigating the risk of tunneling.

Sooting is another concern where black soot may accumulate on the candle’s surface or surrounding areas. This is often a result of an overly long wick or the wrong wick type for the wax used. To mitigate sooting, ensure that the wick is trimmed to the recommended length—usually about ¼ inch above the wax before each lighting. Selecting the appropriate wick that matches the candle’s wax type can also play a vital role in minimizing soot production.

Wick clogging occurs when the wick channels become blocked, leading to poor performance and uneven burning. This can be resolved by occasionally adjusting the wick or ensuring that proper wicking techniques are employed during candle making. Using high-quality wicks made from suitable materials like cotton or wood can help prevent clogging issues and enhance the overall burn. Regular maintenance, such as cleaning the wick and ensuring proper wick placement, can also contribute to improved performance.

Conclusion: Choosing the Right Wick for Your Candle

In the world of candle making, selecting the proper wick is pivotal to achieving the desired burn quality, scent throw, and overall performance of your candle. Throughout this discussion, we delved into the various types of wicks available, including cotton, wood, and hemp wicks, each boasting unique characteristics that influence how a candle burns. The choice of wick can significantly affect factors such as the candle’s burn time, fragrance release, and soot production, thus underscoring the importance of understanding wick dynamics.

As you embark on your candle-making journey, consider the type of wax and fragrance you are using, as this will dictate the compatibility with different wick materials. For instance, a ceramic or glass container might work better with a particular wick type that accommodates a wider burn pool. Furthermore, pay attention to the wick size; a wick that is too small may result in poor throw, while an oversized wick can lead to soot and a flickering flame.

Experimentation is a key component of the candle-making process. As you test various wicks, take notes on the results in terms of burn time, fragrance strength, and visual appeal. Be mindful that external factors like humidity and air circulation can influence these outcomes, so maintaining a controlled environment for experiments is beneficial. Ultimately, the right wick not only enhances the performance of your candle but also enriches the overall aesthetic experience, allowing you to create a product that resonates with your creative vision.

In conclusion, choosing the right wick is an essential step in candle making that transforms your creative ideas into tangible results. By understanding the options available and considering the interplay of various factors, you can make informed decisions that lead to beautifully crafted candles. Embrace both the science and art of candle making, and let your creativity shine through in every unique design.